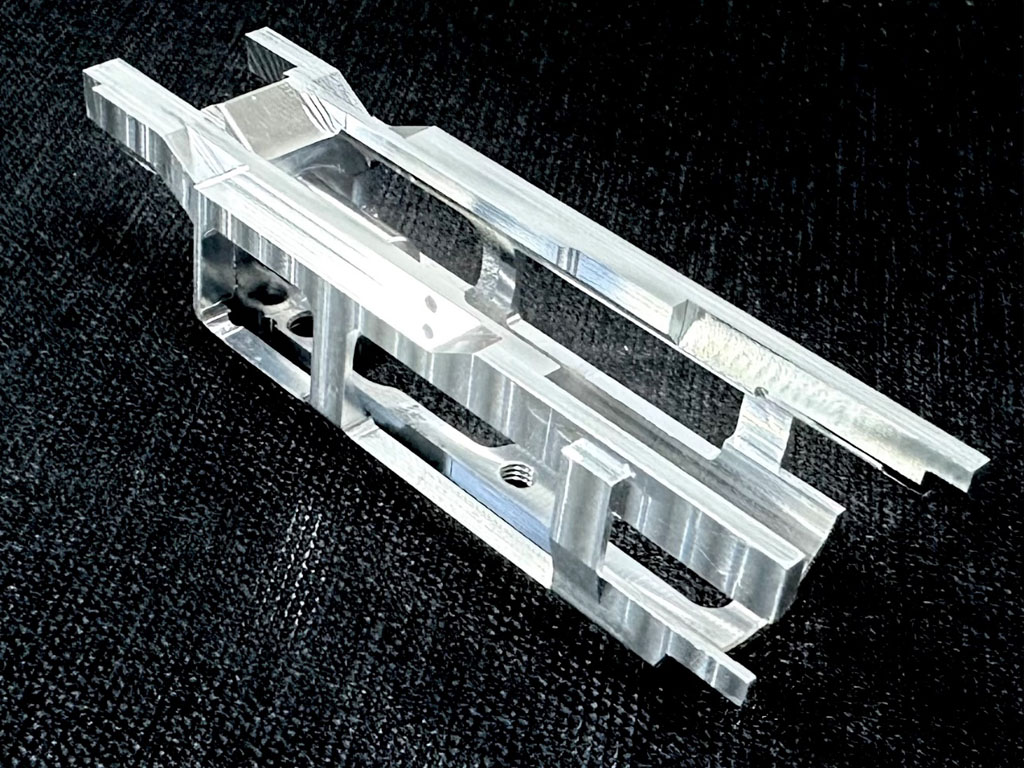

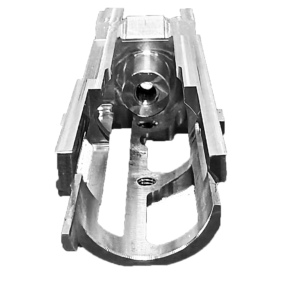

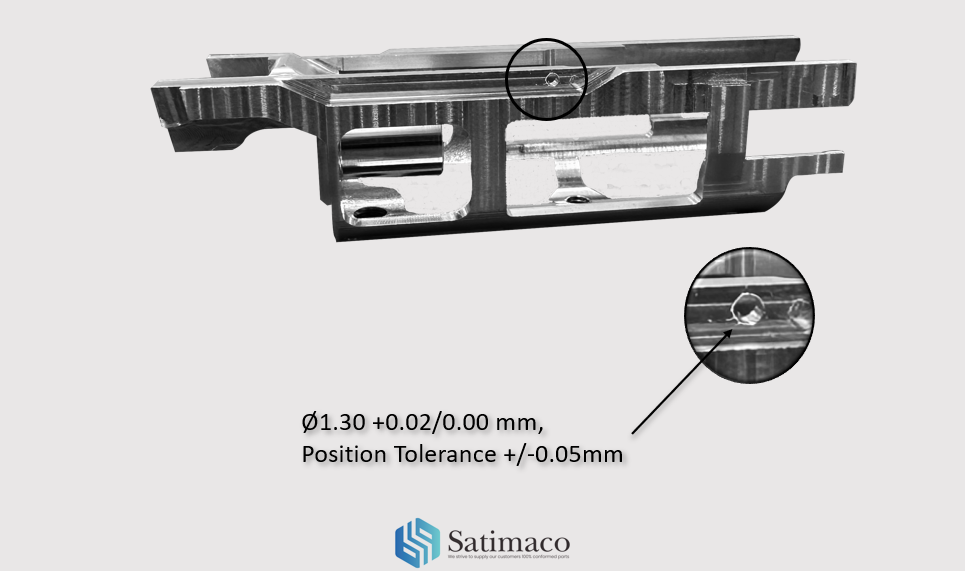

Mastering the art of customized cutters, optimal speed, tailored feed rate, expert fixture, and 6 indexing

The challenge of this part is:

- The material is 7075. The strength release of 7075 material is bigger than that of another aluminum alloy such as the 6000 series. Strength release impacts the variation of the profile after material removal. In addition, the wall thickness after the material is removed is only 0.7 mm. Balancing the firm fixturing while not deforming the profile is very critical.

- Dynamic balance is critical to prevent machine chatter. Fine-tuning the rotation speed to get dynamic balance is therefore needed.

- In CNC machining, the ratio of the diameter of the standard tool bit in the open market to the achievable machining depth is 1:3. This part has several R1 features, which are deep in the 15mm.

This means the ratio between the diameter of the tool bit to the achievable machining depth is 1:15. Therefore, we have to custom-make a tool by reducing the length of the bit so the tool bit is strong enough and will not deflect in the machining.

All parts displayed on this website are intended solely to demonstrate our manufacturing capabilities and are not available for sale. no proprietary information or intellectual property of our customers is disclosed.