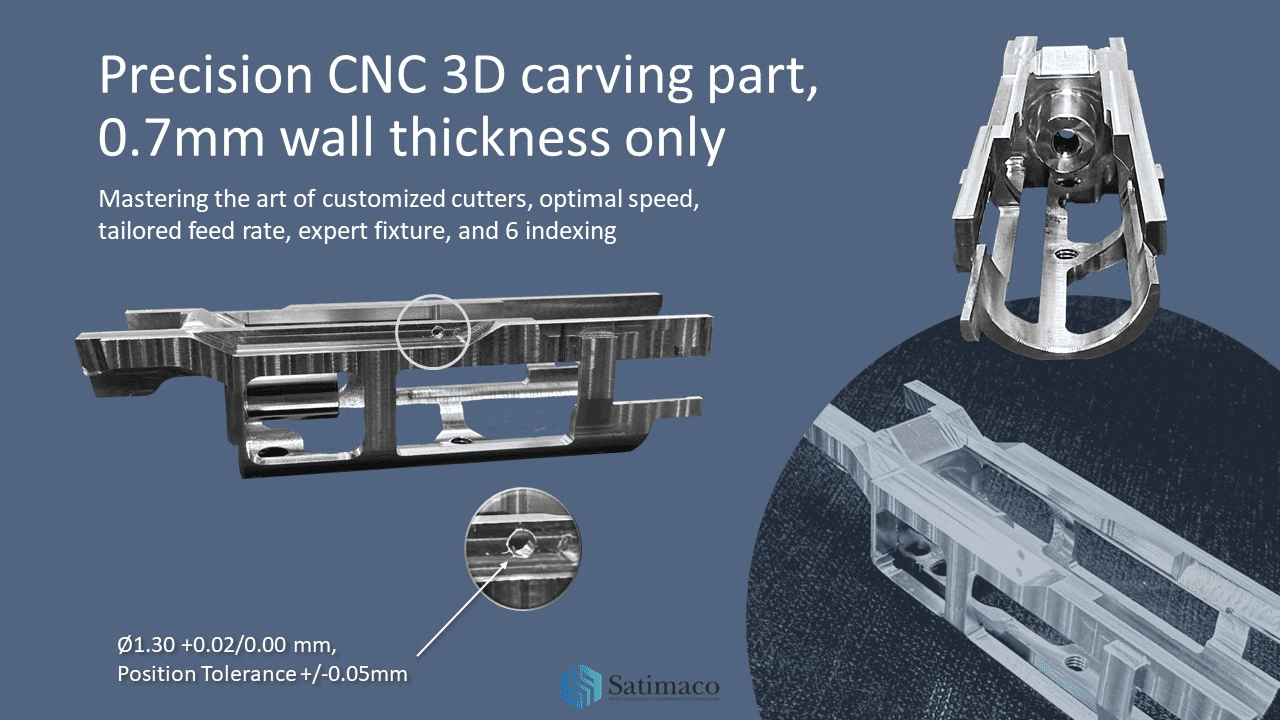

Precision Machining is Our Forte

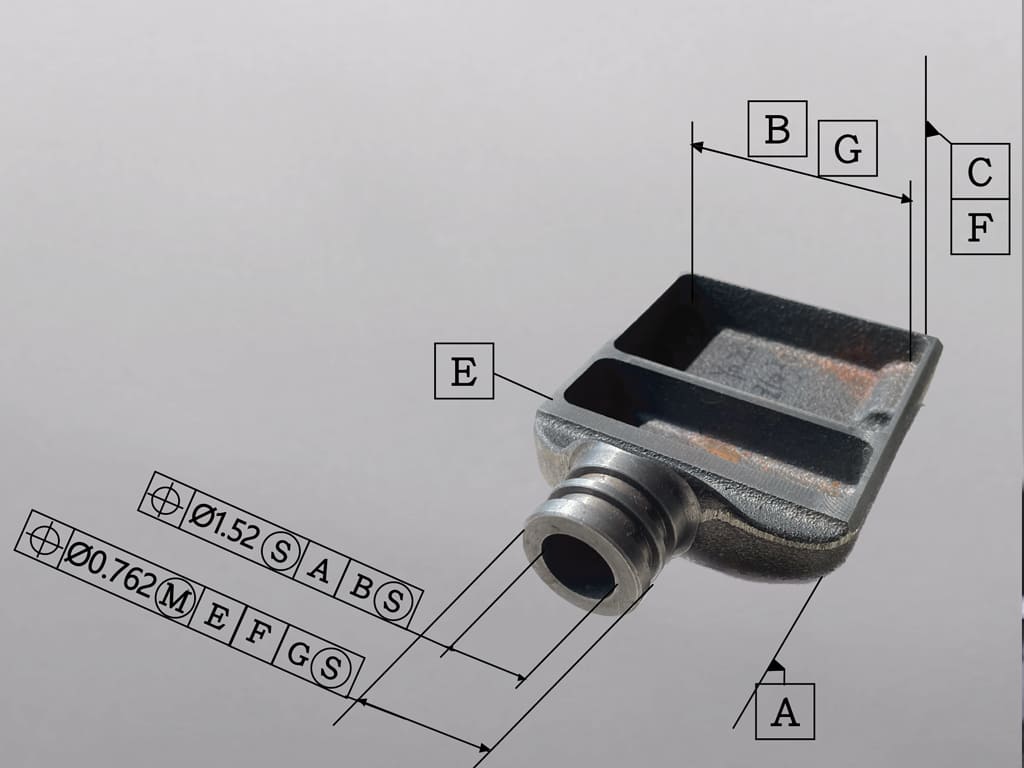

We excel in OEM metal parts machining, meeting high-level demands like GD&T requirements and tight tolerance control. Our engineering team designs processes for stable dimensions and creates specialized fixtures and cutting tools.

Professional Processing

Machining is the company's strength. The company has excellent capabilities in OEM metal parts machining, especially for higher level machining needs.

Strong Engineering Team

The company’s engineering team is capable of designing processes that produce the most consistent sizes, including the design of fixtures and special cutting tools.