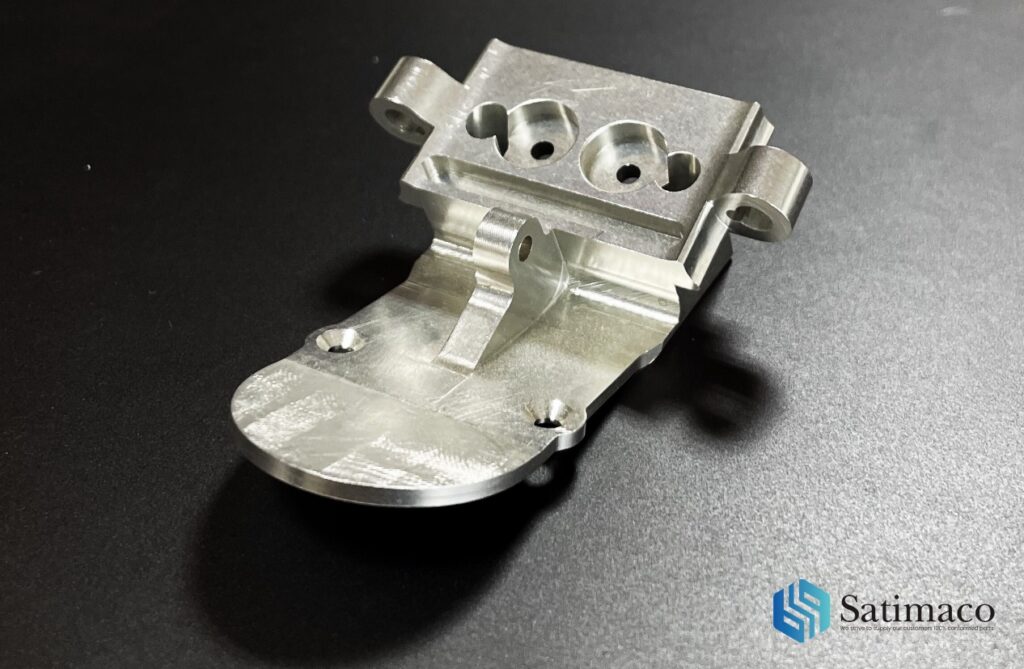

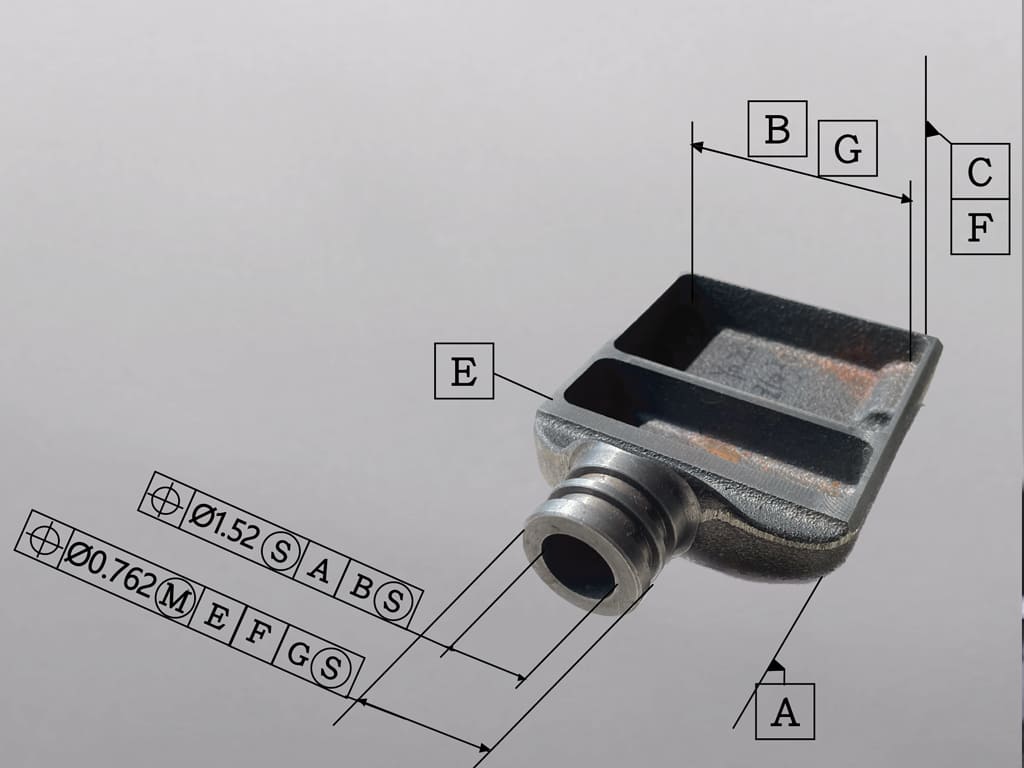

Key Issues for CNC Machining on Aluminum Casting Parts

CNC machining of aluminum casting parts presents unique challenges that require careful consideration to ensure high-quality, precision components. Aluminum casting is widely used across industries like automotive, aerospace, and electronics due to its lightweight nature, excellent corrosion resistance, and thermal conductivity. However, the material’s inherent characteristics, combined with casting defects, can complicate machining processes. In […]

Key Issues for CNC Machining on Aluminum Casting Parts Read More »