Precision Machining

CNC SWISS LATHE TURN PROCESS

Our Swiss Lathe Turn machining is capable of producing complex parts with tight tolerance in high volume. Auto Optical sorting machine is used to control tiny parts such as fasteners, mini. Insert in high volume.

Max. capability size: | Ø 52mm |

Min. capability size: | Ø 1.0mm |

Material: | Aluminum: AL 2011, AL 6061, AL6082, AL 7075 Iron: 12L14, 1215 Stainless steel: SUS 303, SUS 304, SUS 316, SUS430 Copper: C3604, C2600 ,C6801, C6802 |

For material not listed above, please consult with us.

CNC TURN-MILL MACHINING PROCESS

This CNC Turn-Mill multi-tasking machine mainly focuses on turning, with small amount milling as a supplementary function. This process is especially suitable for shaft-type parts.

| Max. capability size: | Ø 320 x 300 mm |

| Min. capability size: | Ø 0.8 mm |

| Material | |

| Aluminum: | AL2011, AL6061, AL6082, AL7075 |

| Stainless steel: | SUS303, SUS304, SUS316, SUS430 |

| Steel Alloy: | SCM 440, SCM 415, SCM 435 |

For material not listed above, please consult with us.

CNC MILL-TURN MACHINING PROCESS

Max. capability size: | Ø 630 x 300 mm |

Min. capability size: | Ø 2.0 mm |

Material: | Aluminum: AL2011, AL6061, AL6082, AL7075 Stainless steel: SUS303, SUS304, SUS316, SUS430 Steel Alloy: SCM 440, SCM 415, SCM 435 |

For material not listed above, please consult with us.

This CNC mill-turn multi-tasking machining mainly focuses on milling large amounts and a small amount of turning machining. This process is especially suitable for complex geometric shapes requiring tight GD&T.

CNC MILLING & TAPPING MACHINING PROCESS

Our four-axis CNC milling and tapping machine can mill parts with complex geometries and handle threading for various internal thread sizes and types. Our professional engineering team excels in designing fixtures for quick turnaround and consistent precision, as well as creating specialized cutting tools to produce intricate features such as very small radii or protruding squares.

DD mechanism (Direct driving) is introduced to our machine which offers

higher speed and acceleration, higher precision and accuracy.

Max. capability size: | 700 x 450 x 500 mm |

Material: | Aluminum: AL2024, AL5052. AL6061, AL6082, AL7075, ADC12, A380, A356 Stainless steel: SUS303, SUS304, SUS316, SUS410 Steel Alloy: SCM 415, SCM 420, SCM 439, SCM 440 Ductile iron: FCD 400, FCD 450, FCD 500, FCD 600 |

For material not listed above, please consult with us.

CNC 3D ENGRAVING MACHINING PROCESS

In our 3D engraving machining process, the four axis, combined with four-axis simultaneous motion, allows for enhanced movement beyond the traditional XYZ directions. This set up is capable of machining part wit complex geometries and GD & T.

Max. capability size: | To be consulted with us for individual case. |

Material: | Aluminum: AL2024, AL5052. AL6061, AL6082, AL7075 |

For material not listed above, please consult with us.

CNC DISK-TYPE MACHINING PROCESS

Our four-axis CNC milling machine integrated with DD mechanism (Direct driving) may perform turning operation, this is specialized in machining

disk-type components, efficiently handling both large and small diameter parts.

|

Max. capability size: |

Ø 550mm, Z-axis 600mm |

|

Material: |

Aluminum: AL2024, AL5052. AL6061, AL6082, AL7075 Carbon steel S45C |

For material not listed above, please consult with us.

CNC CURVED SURFACE MACHINING PROCESS

Our four-axis CNC milling machine integrated with DD mechanism (Direct driving ) enable machine to do turning operation, and may perform complex curved surface machining such as camshafts and other components with regular curvatures. DD mechanism also ensure the smoothness and consistency of curved surface.

Max. capability size: | 700 x 450 x 500 mm |

Material: | Aluminum: AL2024, AL5052. AL6061, AL6082, AL7075, A356 |

For material not listed above, please consult with us.

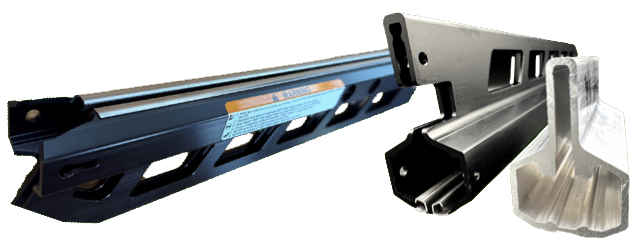

Assembly

Step 1:

Aluminum Profile

Step 2:

Control Profile Dimension

Step 3:

Machine Profile to print

Step 4:

Control Machining Dimension

Step 5:

Clean up surface flaws

Step 6:

Machined profile

Step 7:

Cosmetic Inspection

Step 8:

Sheet Metal Forming Wear Channel

Step 9:

Control Wear Channel dimensioning

Step 10:

Assemble the Wear Channel and labeling magazine