CNC Machining Effects on Stress and Dimensional Stability

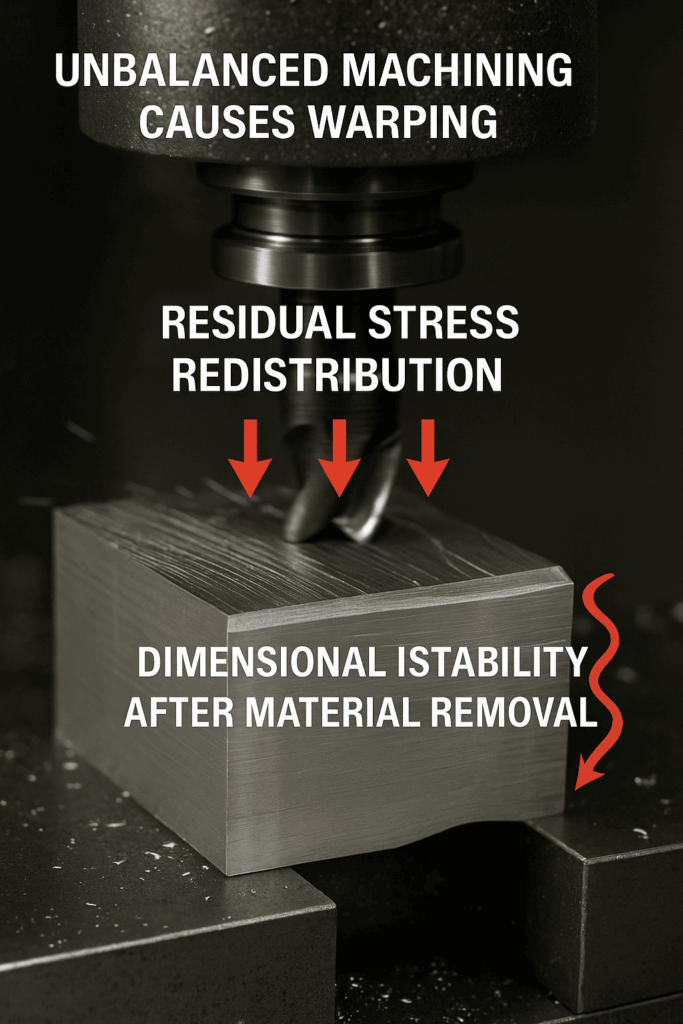

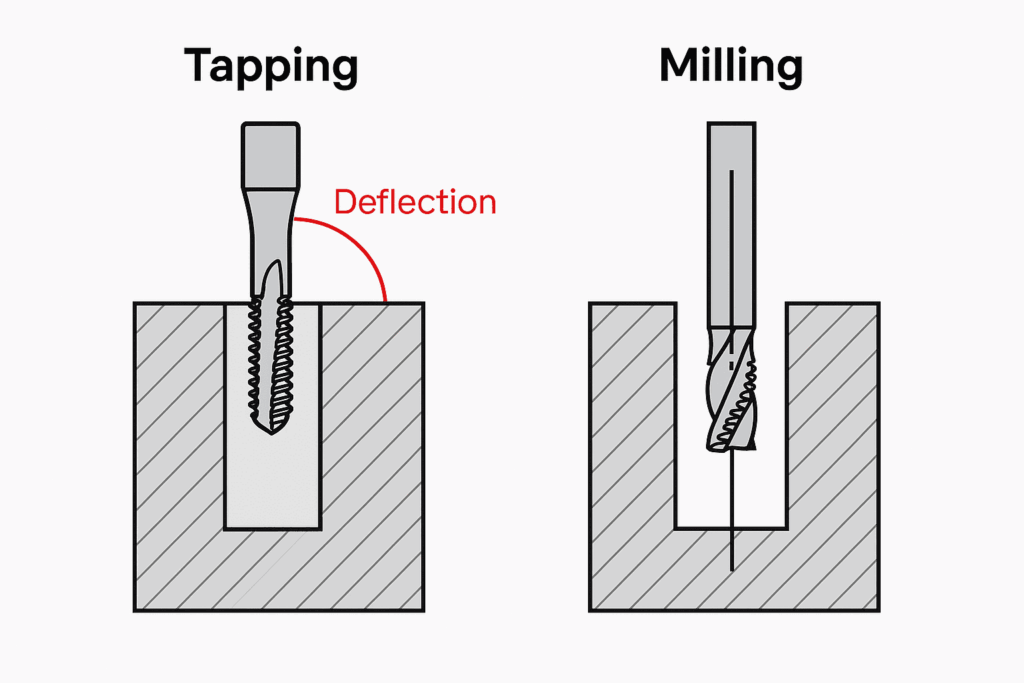

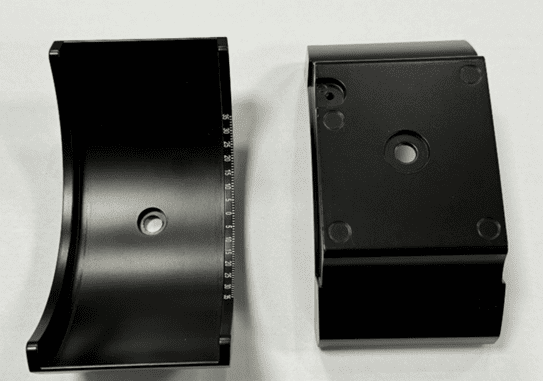

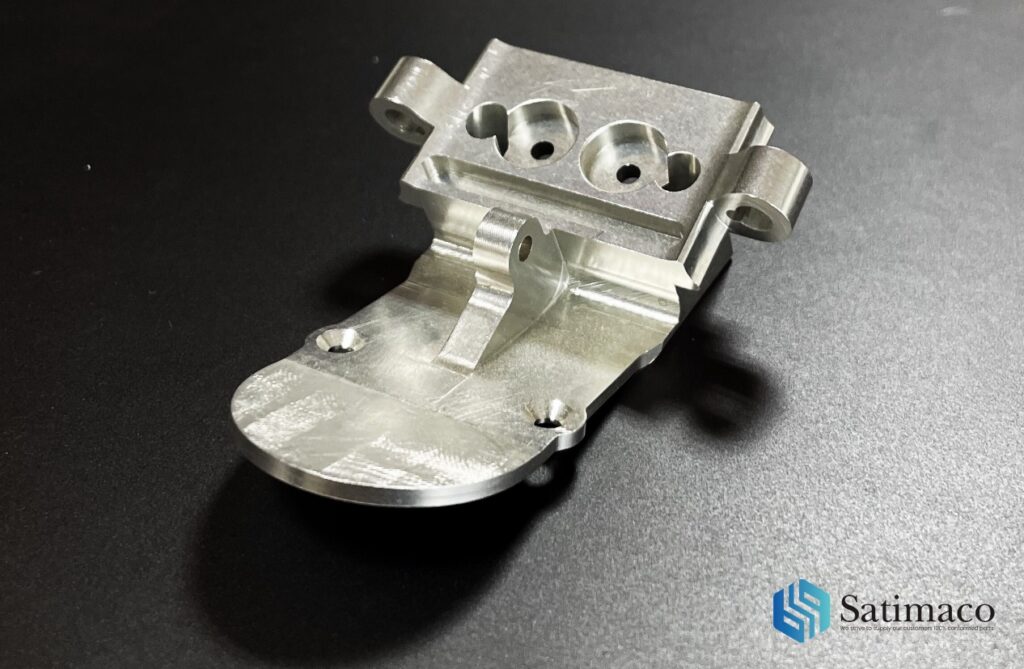

Understanding how CNC machining processes affect internal stress and dimensional stability is essential for producing reliable and accurate parts. Each stage of machining — from rough cutting to finishing — can influence not only the tensile stress within the material but also cause stress release that results in part deformation and unstable dimensions. This section […]

CNC Machining Effects on Stress and Dimensional Stability Read More »