CNC Machining Thin-Walled Parts: Mastering the Challenges

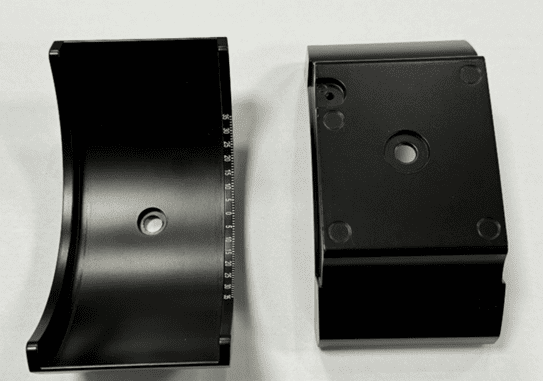

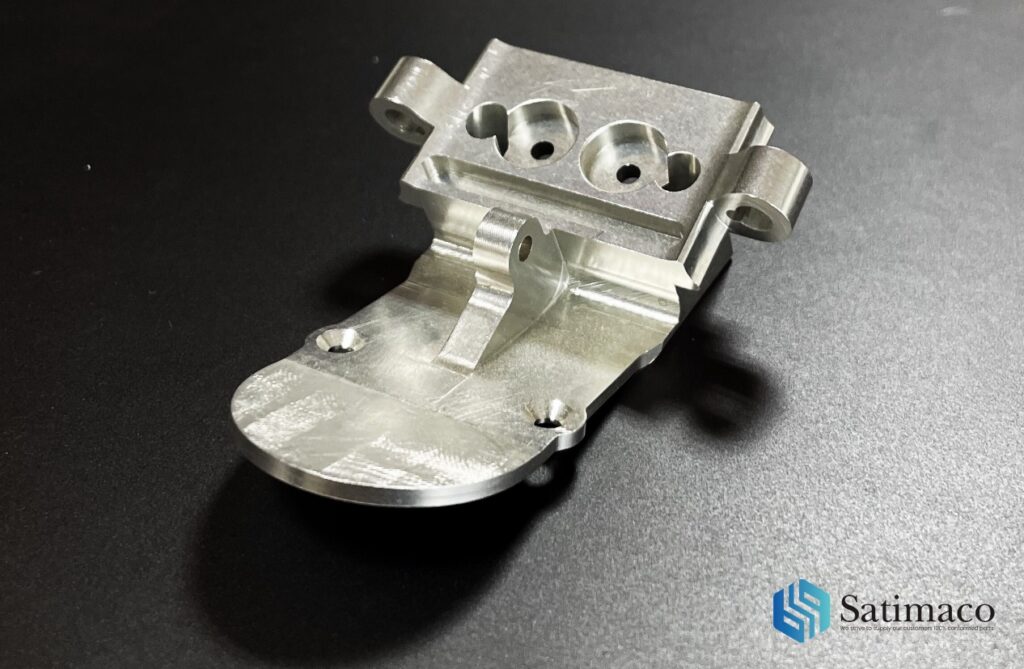

Introduction Recently, we tackled a challenging project involving a small, complex workpiece that required exceptional precision. This experience demonstrated our ability to overcome machining difficulties associated with thin-walled structures and intricate geometries. In this article, we share the challenges we faced, our solutions, and how our expertise delivered outstanding results. Whether you’re looking for CNC […]

CNC Machining Thin-Walled Parts: Mastering the Challenges Read More »