Industries Served

Medical Industry

Construction

Military

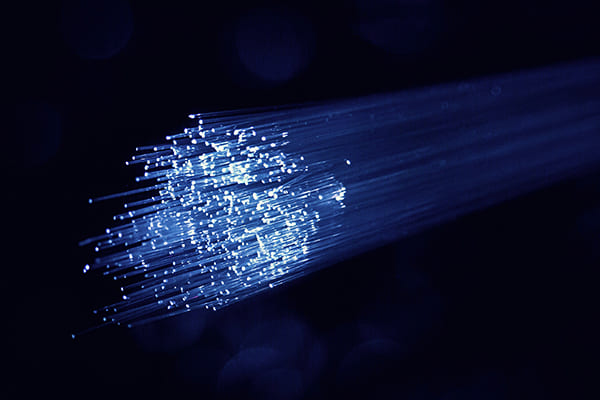

Fiber Optic

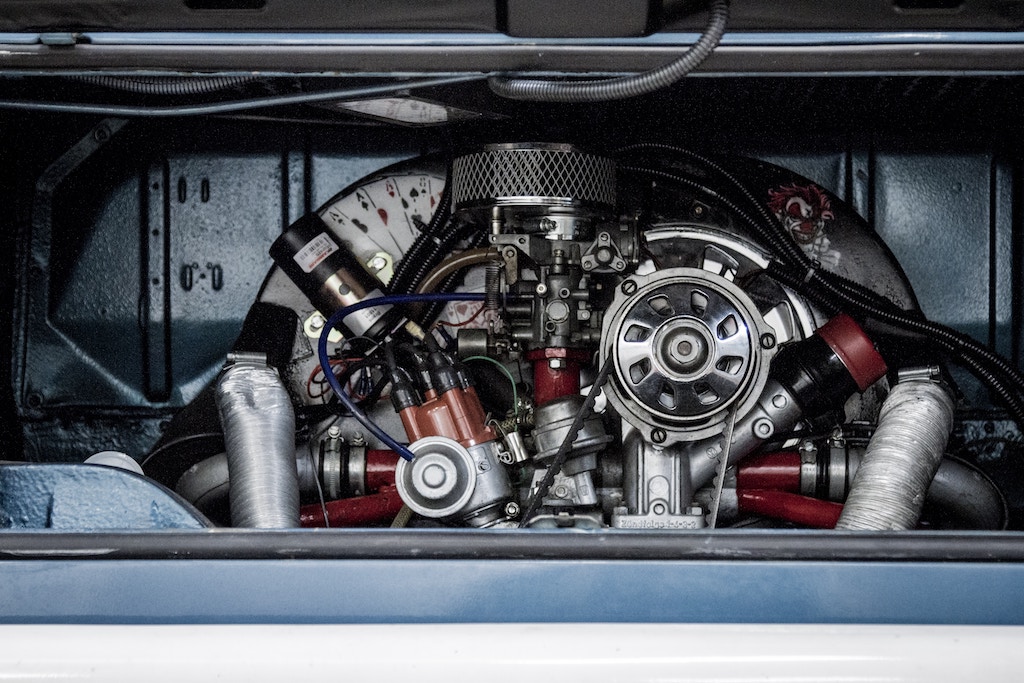

Auto

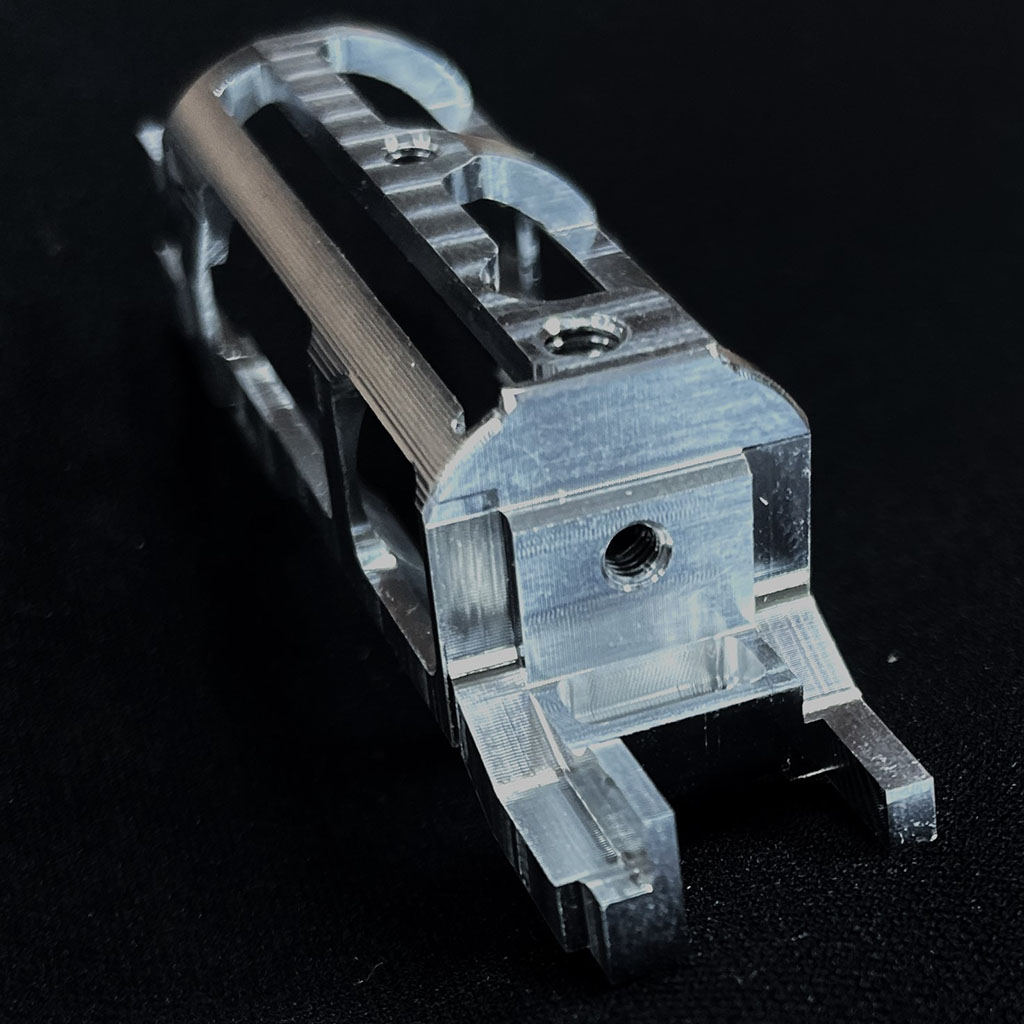

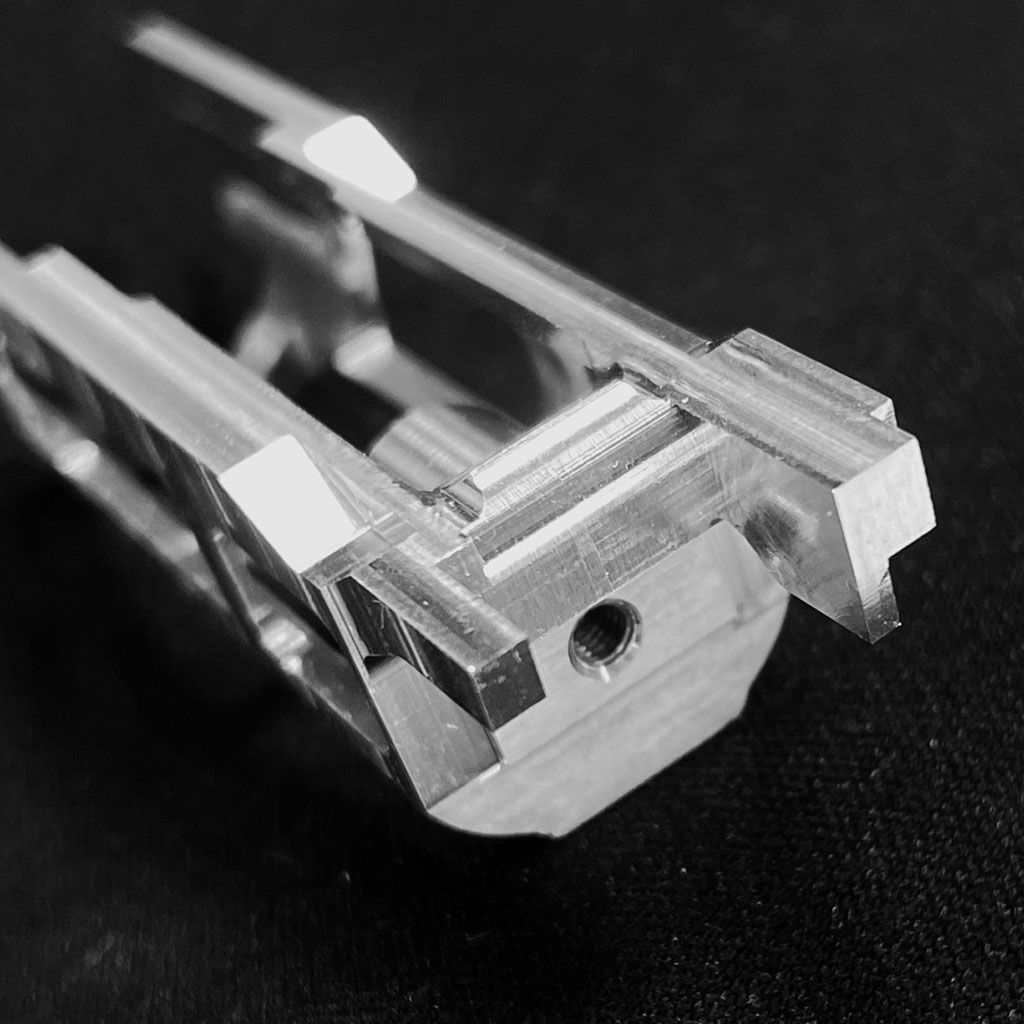

Airsoft

Mastering Complexity with Our CNC Machining Expertise:

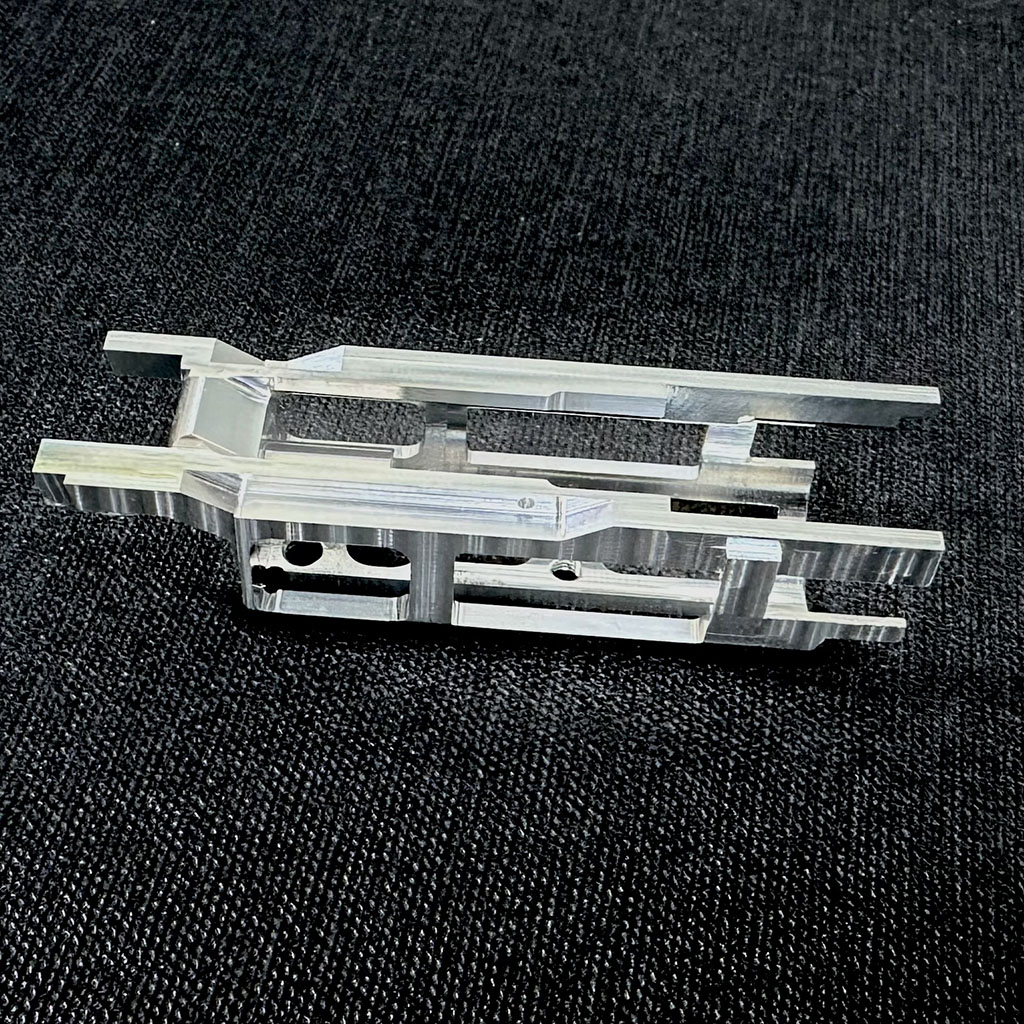

4-Axis CNC Simultaneous Machining with Fully Engraved Parts

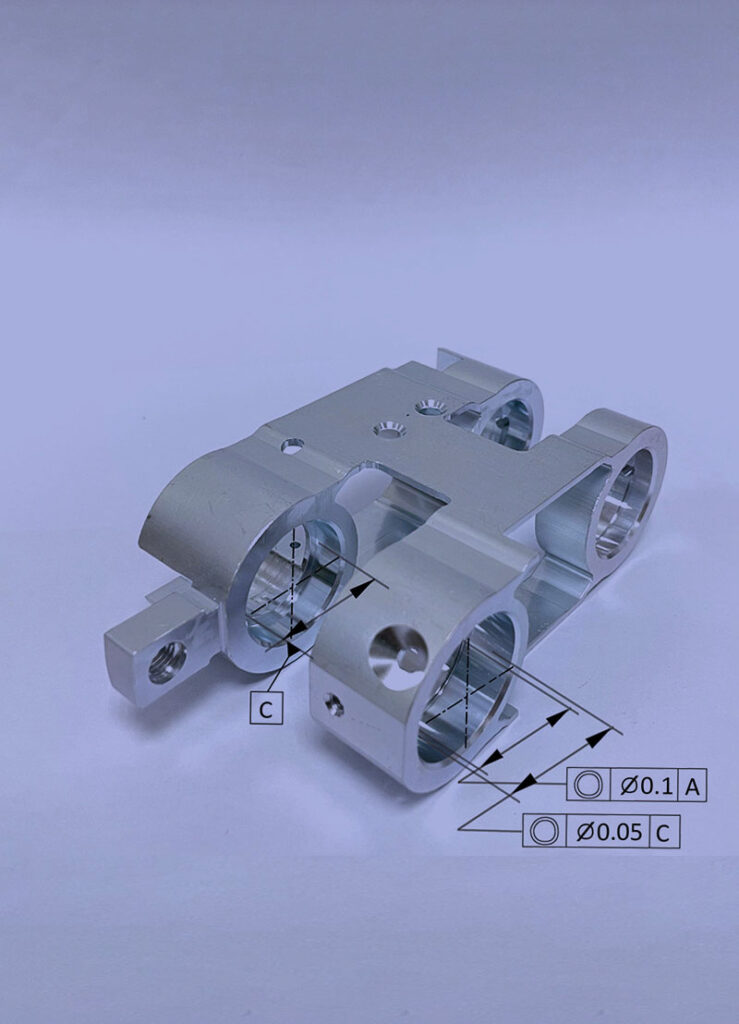

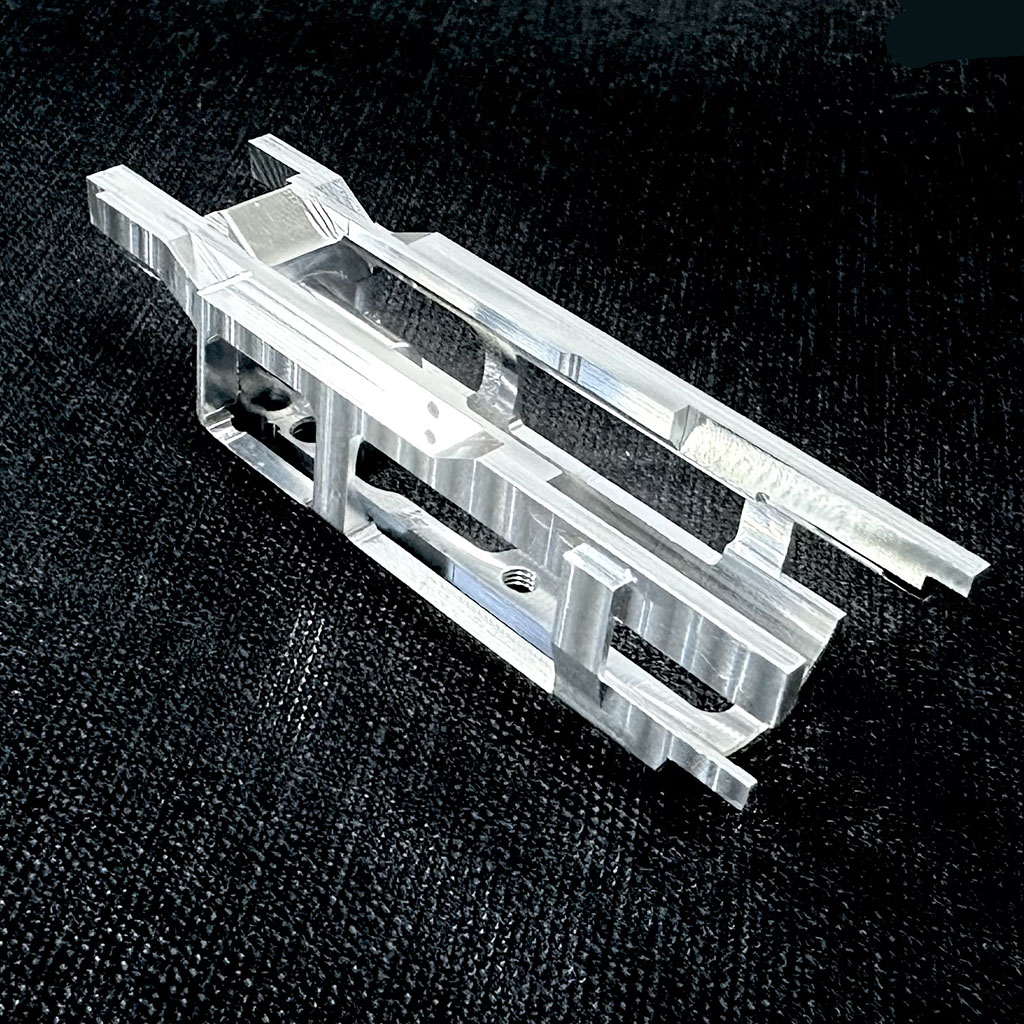

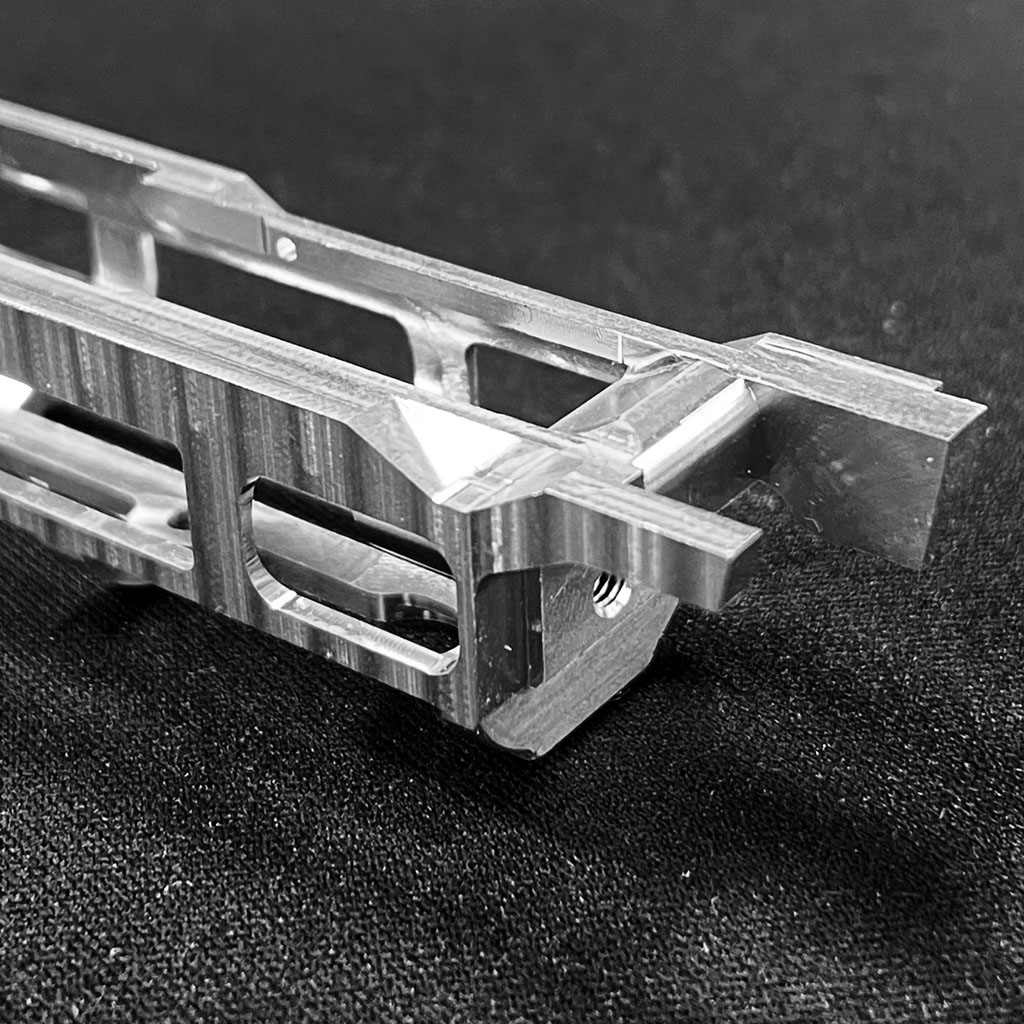

Workpiece Alignment vs. Fixture & Machine Coordinates

To ensure repeatability and consistency, the play between the workpiece and the fixture must be prevented. The fit between the fixture and the workpiece is precisely controlled within a tolerance of 0.01mm.

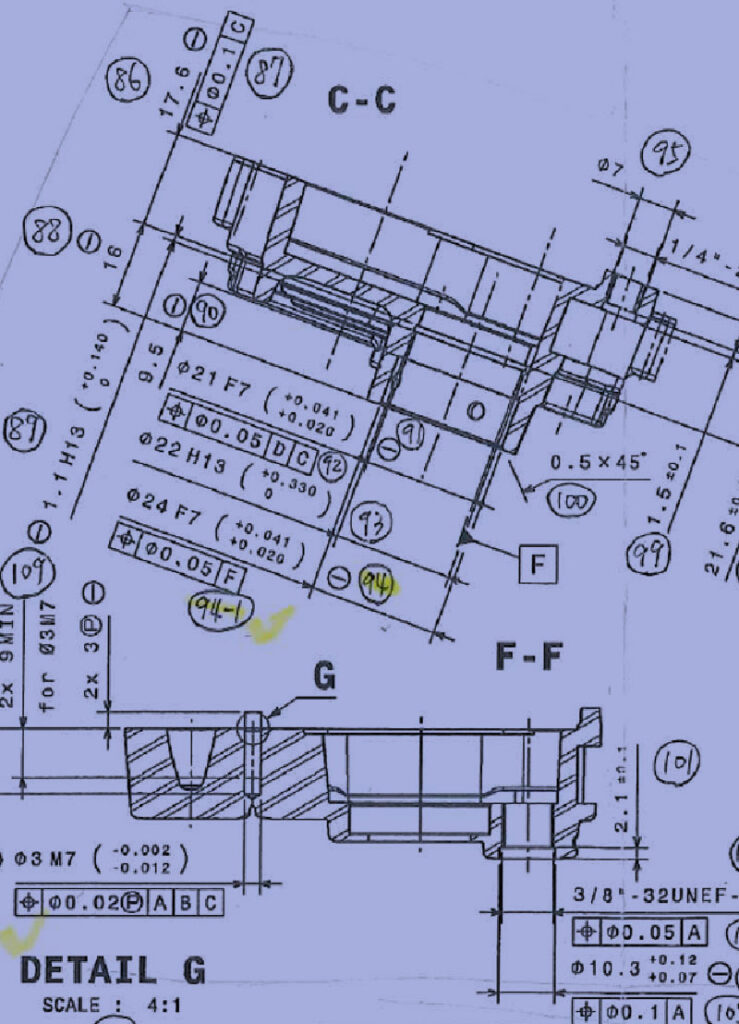

Strict dimension tolerance

.X +/-.3

.XX +/-.15

.XXX +/-.05

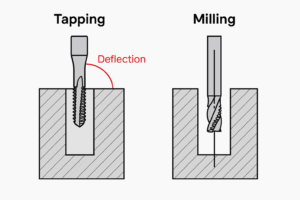

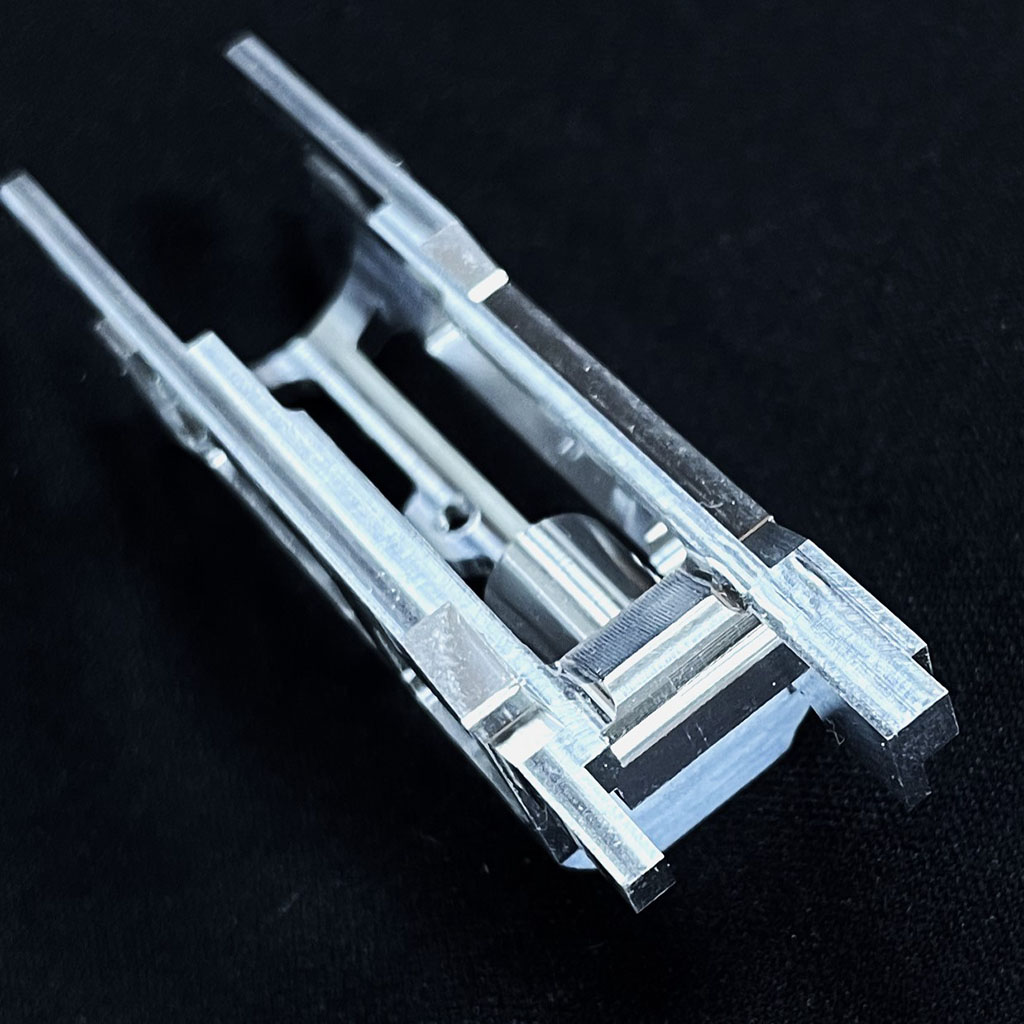

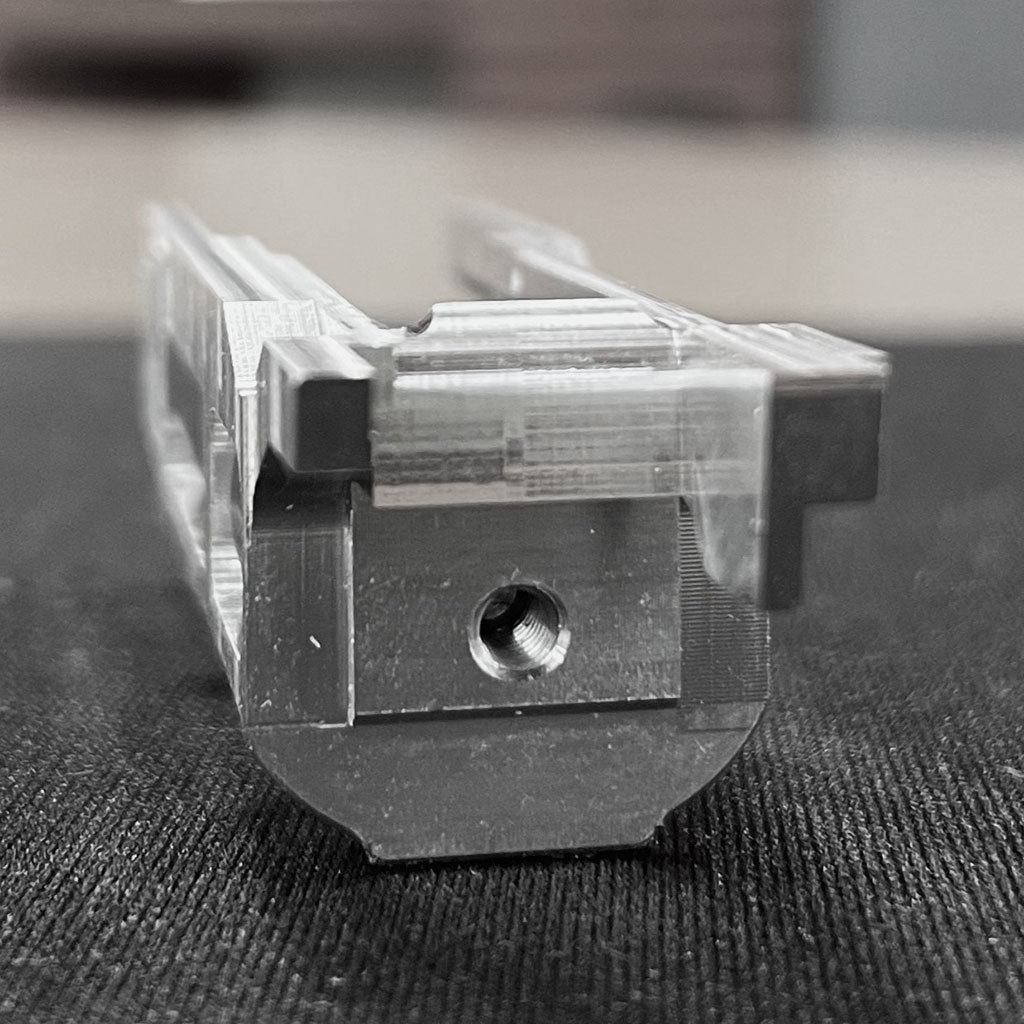

Deep Slot Machining

Machining a deep slot within the workpiece is highly challenging due to tool access limitations and the rigidity required of the cutting tool.

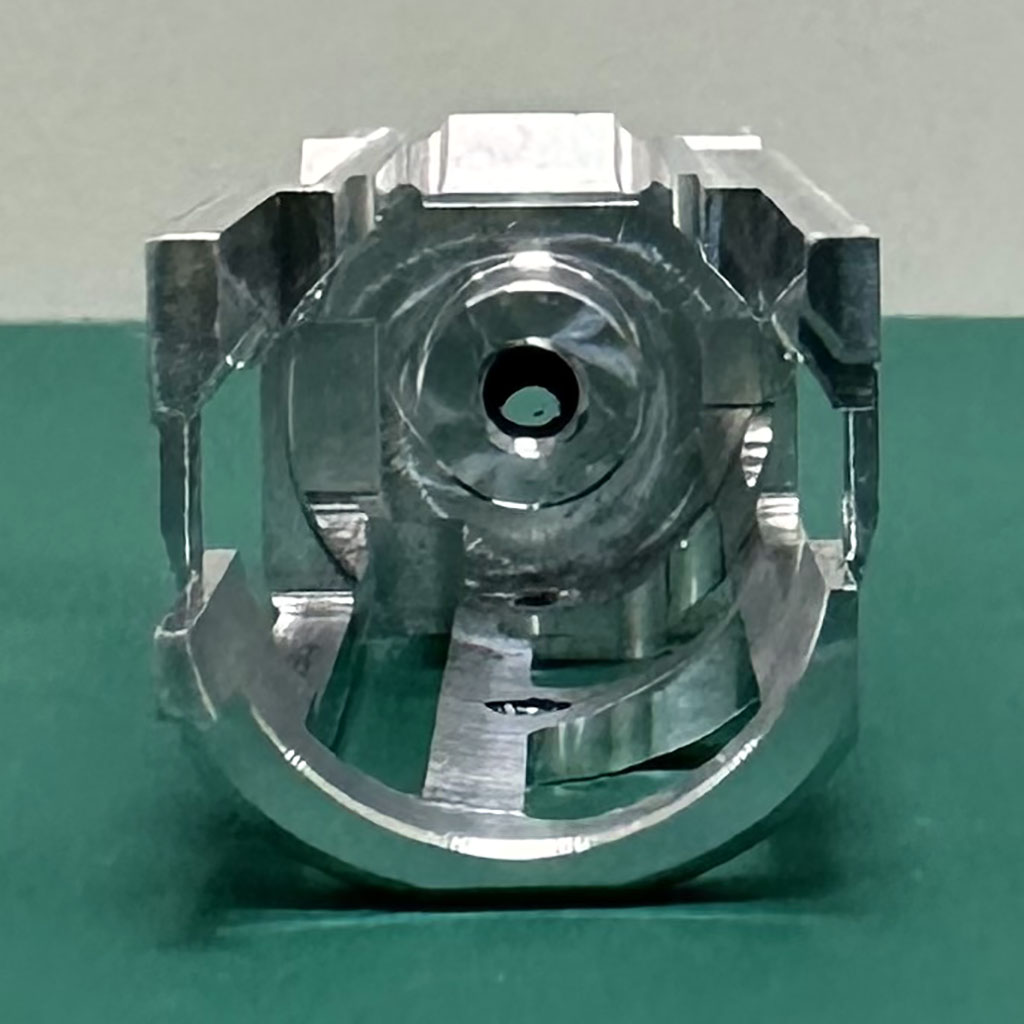

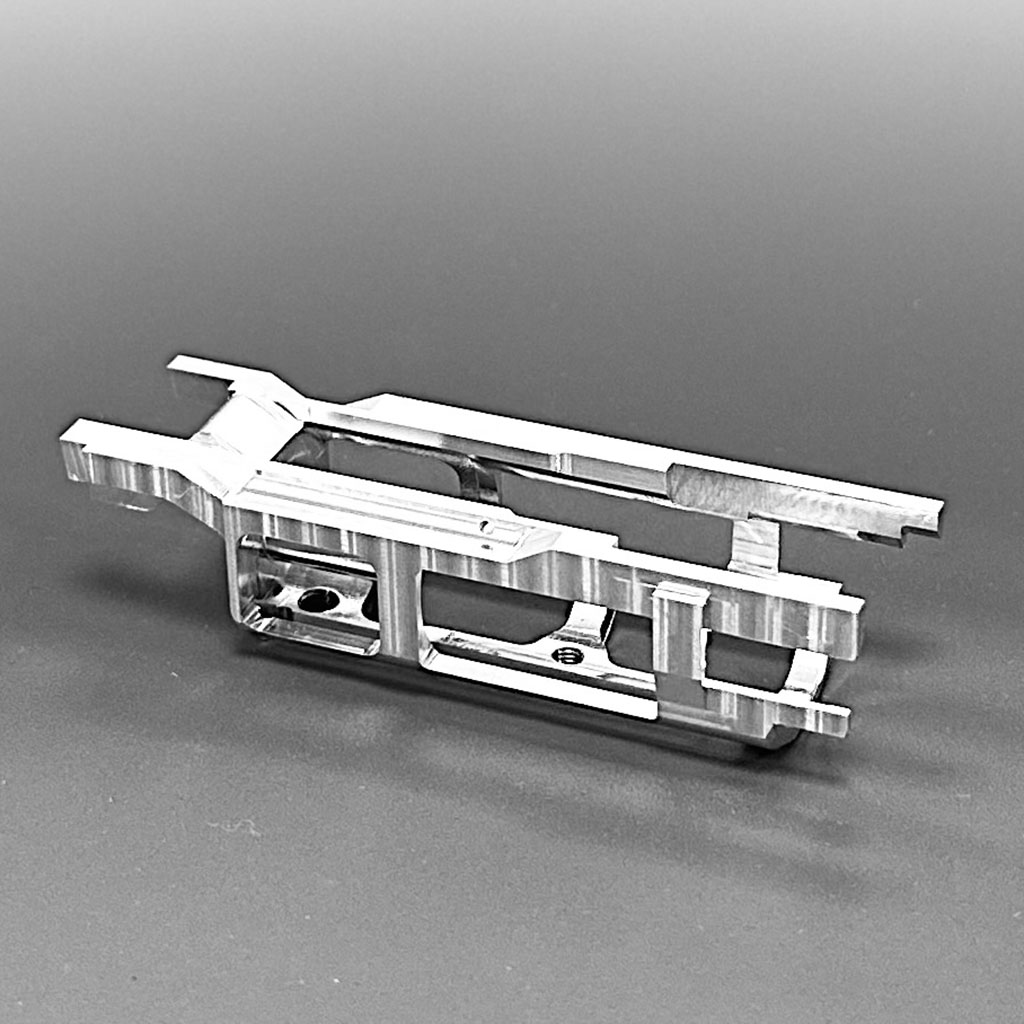

360-Degree

Machining Fixture

We created a specialized fixture that allows for comprehensive 360-degree CNC machining. This fixture enables access to all angles, ensuring uniformity and precision.

Advanced CNC Software

We invested in high-tech software capable of adapting to 5-axis CNC machining, enhancing our ability to handle intricate and precise machining tasks with greater efficiency and accuracy.

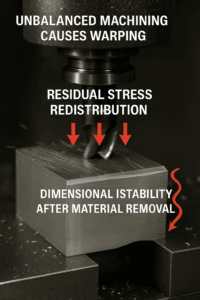

7075 Aluminum Machining

Machining 7075 aluminum alloy presents significant challenges due to its high internal stress, making it prone to warping and deformation.

Precision Cutting Tool

We utilized a specialized cutting tool with dimensions of 4mm x 55mm for hole drilling, ensuring precise cuts and maintaining the material's integrity.

Custom Anti-Chatter Tool

We developed a unique cutting tool specifically designed to minimize chatter on the outer diameter, ensuring a smooth and accurate finish.

A special introduction to our integration fabrication service

Quantify Product with a quality team

Even Drawing With Over 100 Dimensions

Our Quality Control on custom made metal parts starts at the beginning with careful analyze of customer’s drawing to call out well defined engineering process, so to produce repeatable products & features.