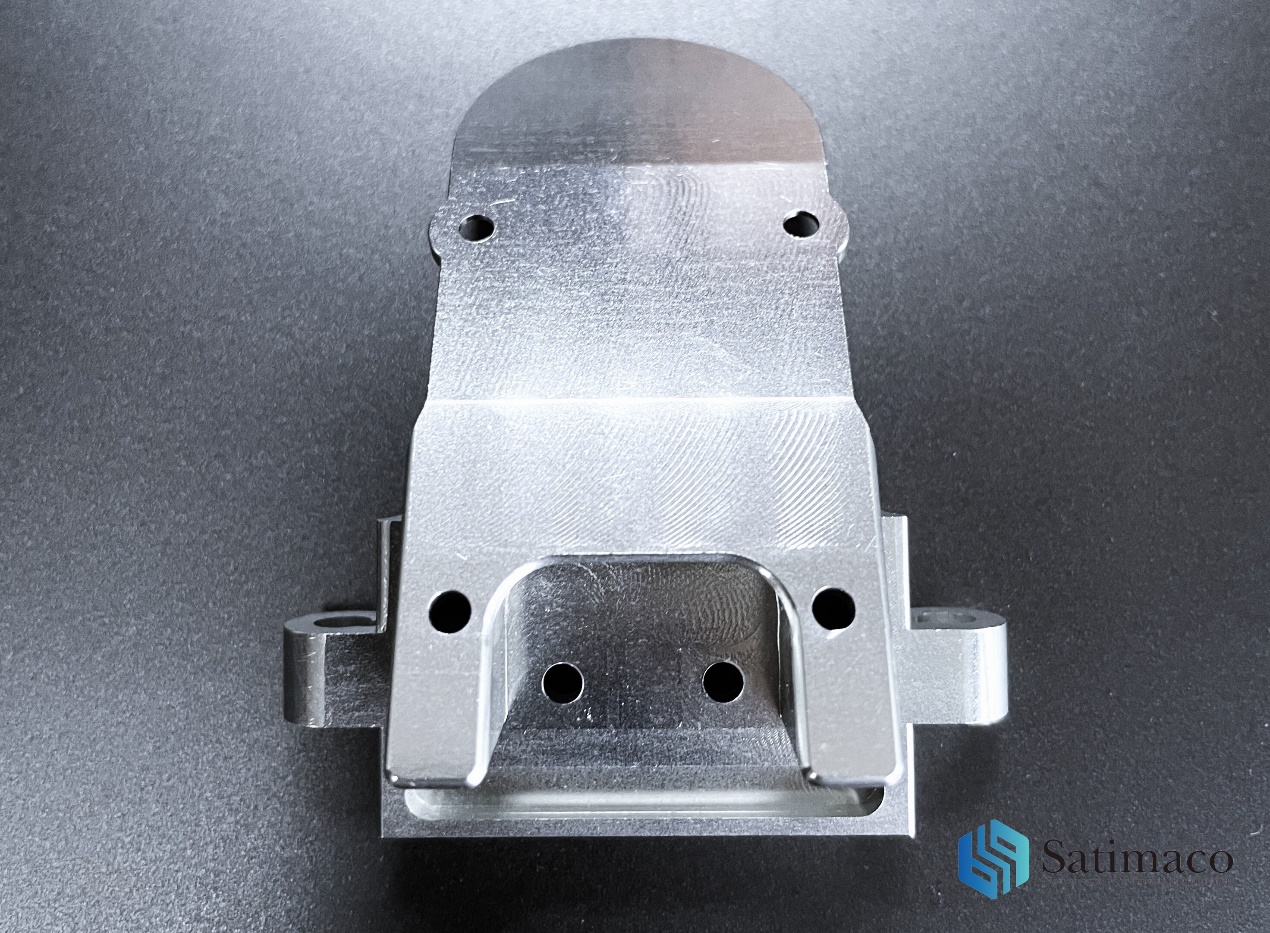

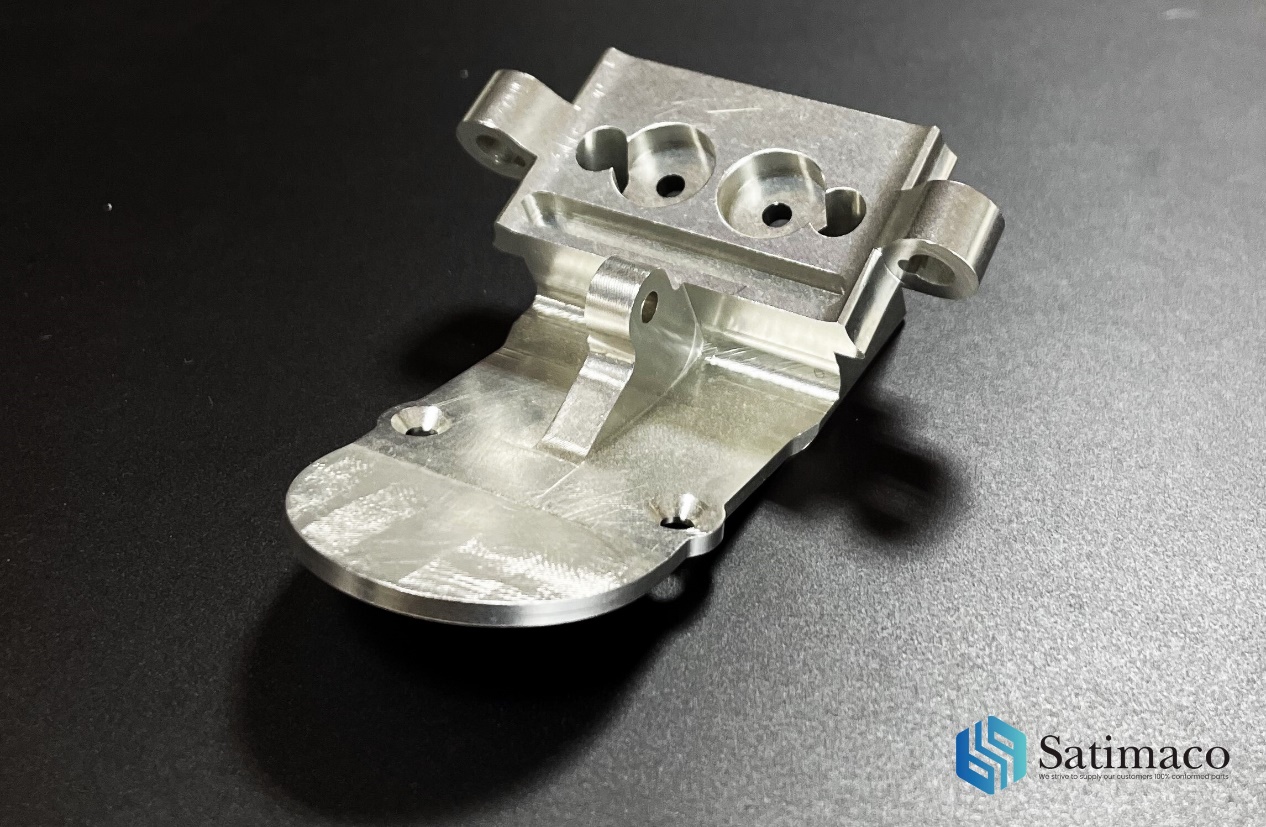

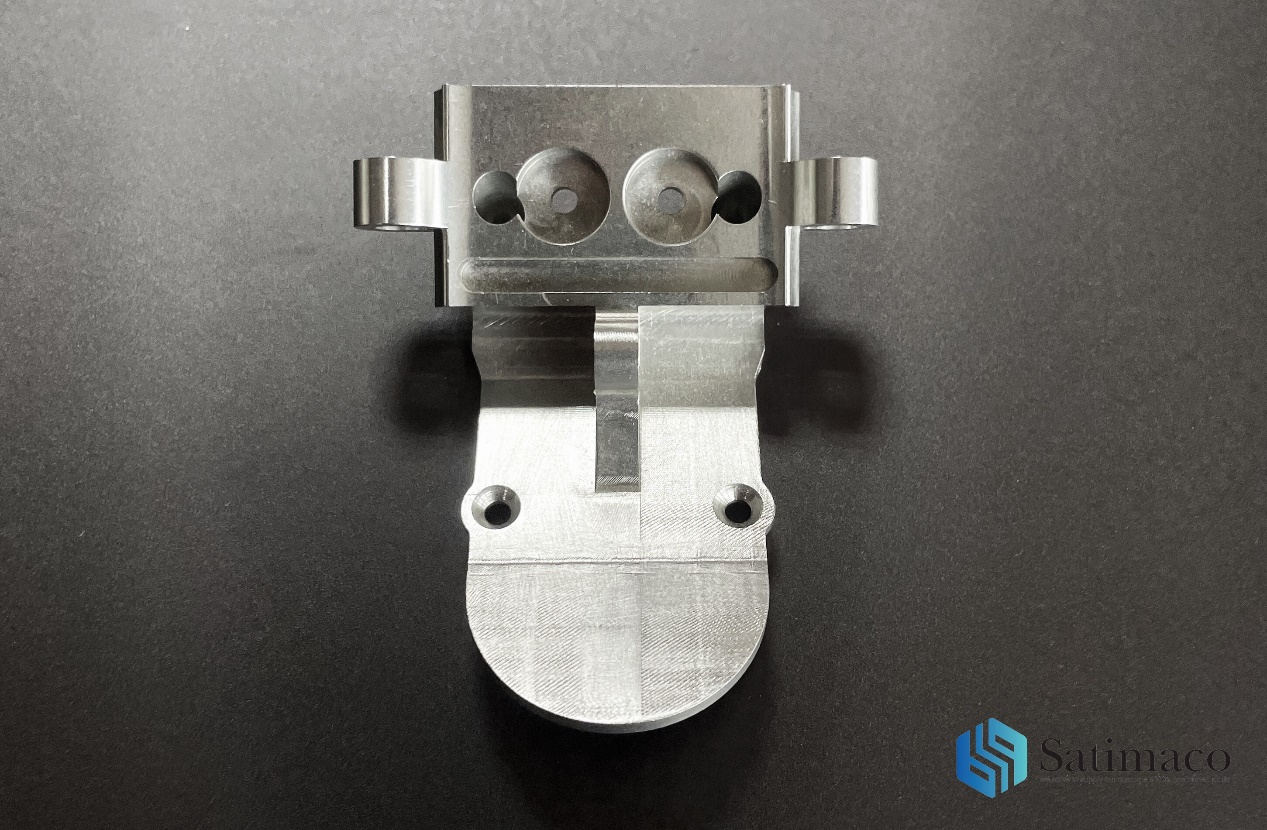

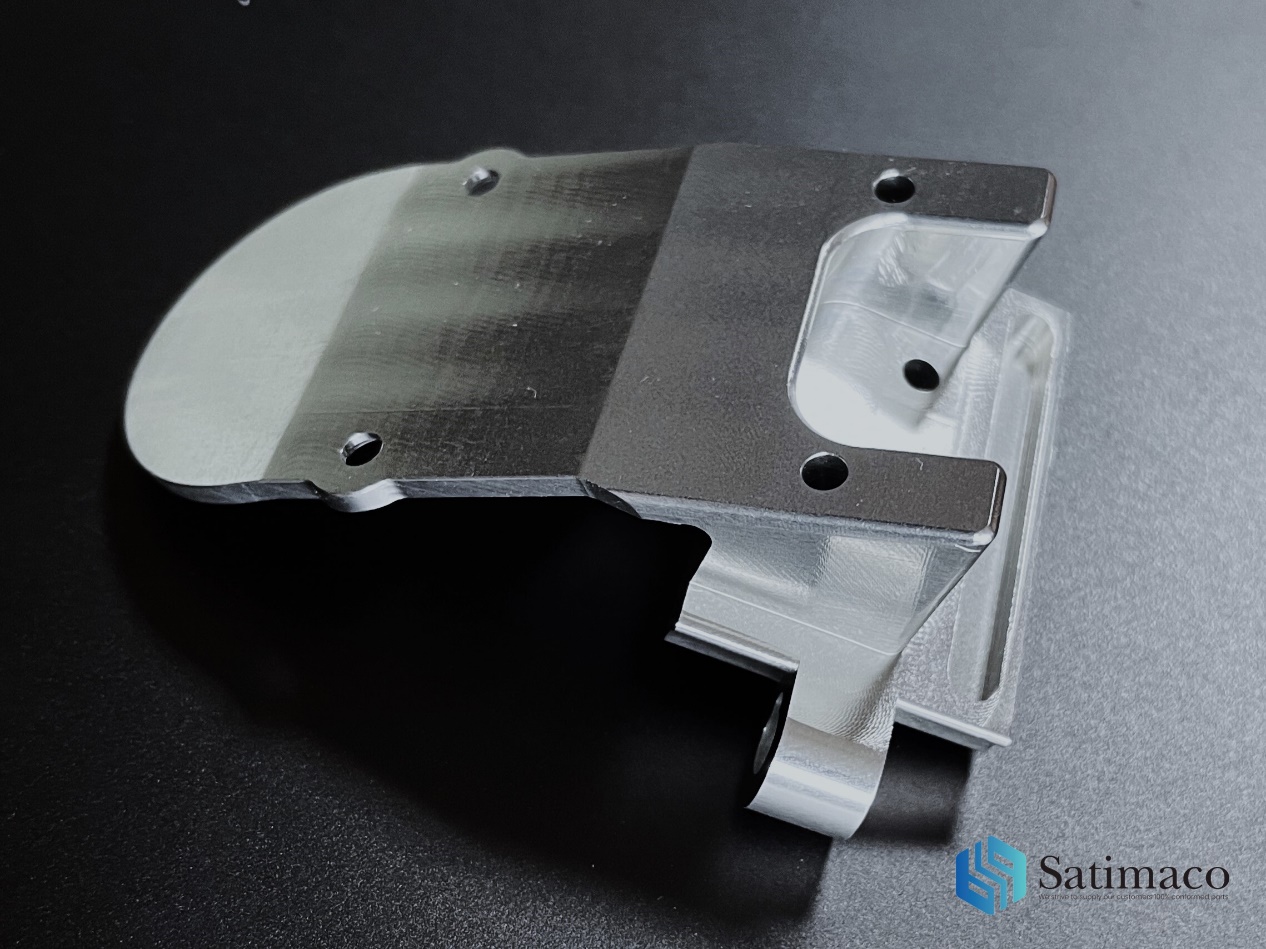

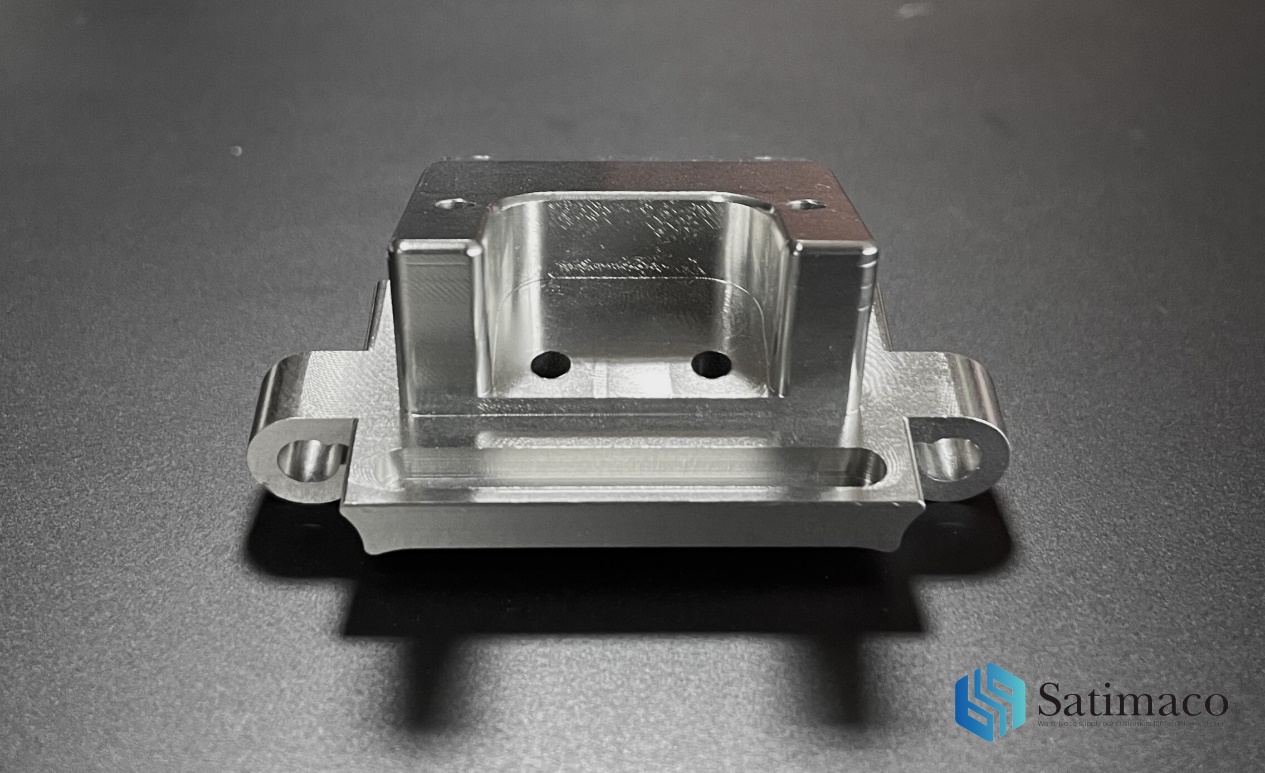

In the CNC engraving process for this part, the fourth axis, combined with four-axis simultaneous motion, allows for enhanced movement beyond the traditional XYZ directions. This setup integrates an additional rotational axis that enables the workpiece to rotate, providing greater flexibility and access to complex geometries.

Key Features of This Machining Method:

- Enhanced Flexibility: The fourth axis allows for the rotation of the workpiece, enabling the tool to approach the part from various angles and positions, which is particularly useful for intricate engravings and complex shapes.

- Improved Access to Difficult Areas: With the ability to rotate the workpiece, this method provides better access to areas that would be challenging or impossible to reach with a standard three-axis machine.

- Higher Precision and Detail: The simultaneous movement of all four axes allows for smoother transitions and more precise control over the toolpath, leading to higher accuracy in detailed engravings.

- Reduced Setup Time: By eliminating the need for multiple setups and repositioning of the workpiece, this method can significantly reduce setup time and improve overall efficiency.

- Complex Geometry Handling: This method is ideal for creating parts with complex geometries and intricate designs, such as sculptures, molds, and intricate components in aerospace and medical applications.

Is This a High-Level Machining Technique?

Yes, this is considered a high-level machining technique. Here’s why:

- Technical Complexity: The coordination of four-axis simultaneous motion requires advanced programming and precise control, making it more complex than standard three-axis machining.

- Skill Requirement: Operators and programmers need specialized knowledge and experience to effectively utilize four-axis CNC machines, including understanding the dynamics of the additional rotational axis.

- Advanced Equipment: The machines capable of performing four-axis simultaneous machining are typically more advanced and expensive, reflecting the higher level of technology involved.

- Application in High-Precision Industries: This technique is often used in industries that demand high precision and intricate details, such as aerospace, medical device manufacturing, and fine art sculpture, underscoring its advanced nature.

By leveraging the fourth axis and four-axis simultaneous motion, this method enables the creation of complex, detailed, and high-precision parts, marking it as a sophisticated and high-level machining technique.