In the fast-paced world of product development, delays can be costly. One common—but often overlooked—cause of delay is the lack of early communication between the customer and the supplier about how a custom part functions and interacts with its mating components. As an experienced metal parts supplier, we’ve seen it time and again: a part passes inspection but fails during assembly. Why? Because the real-world assembly context wasn’t shared until it was too late.

The Real Cost of Late-Stage Design Revisions

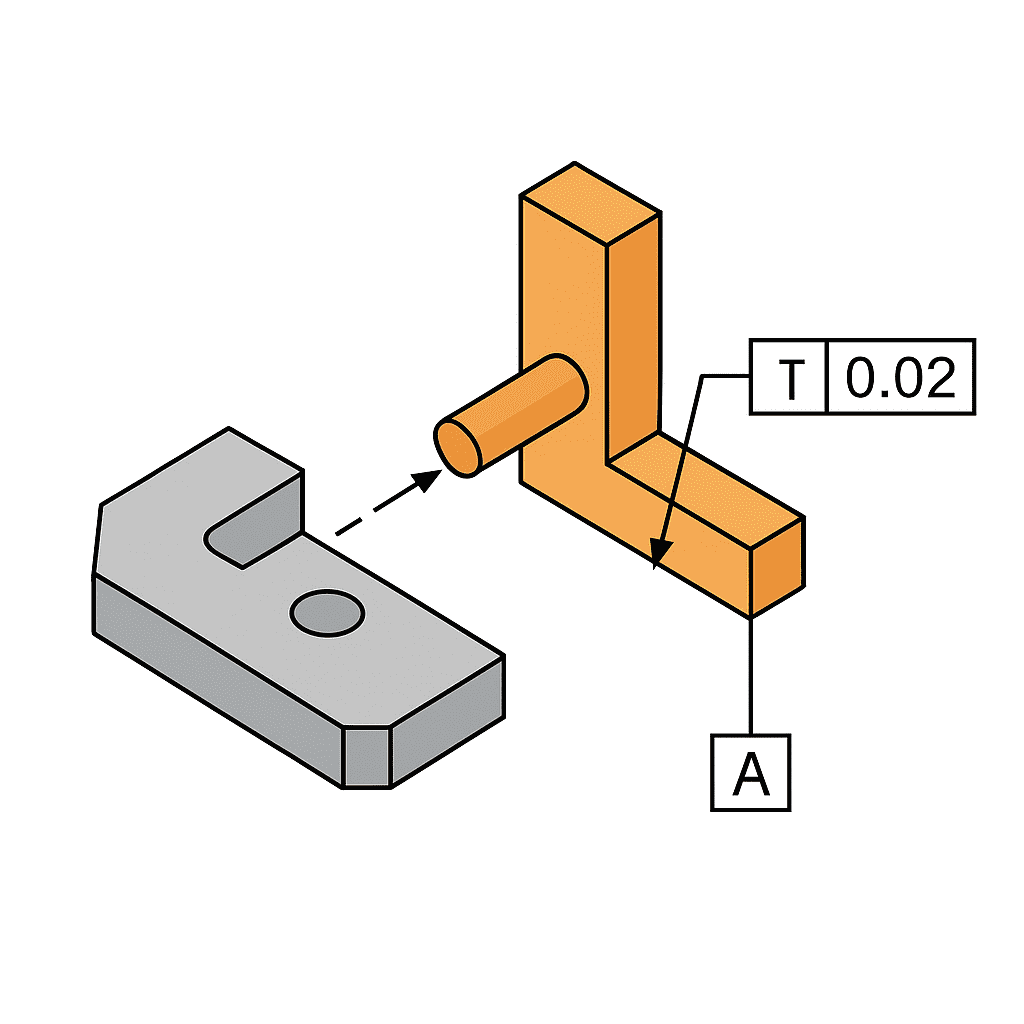

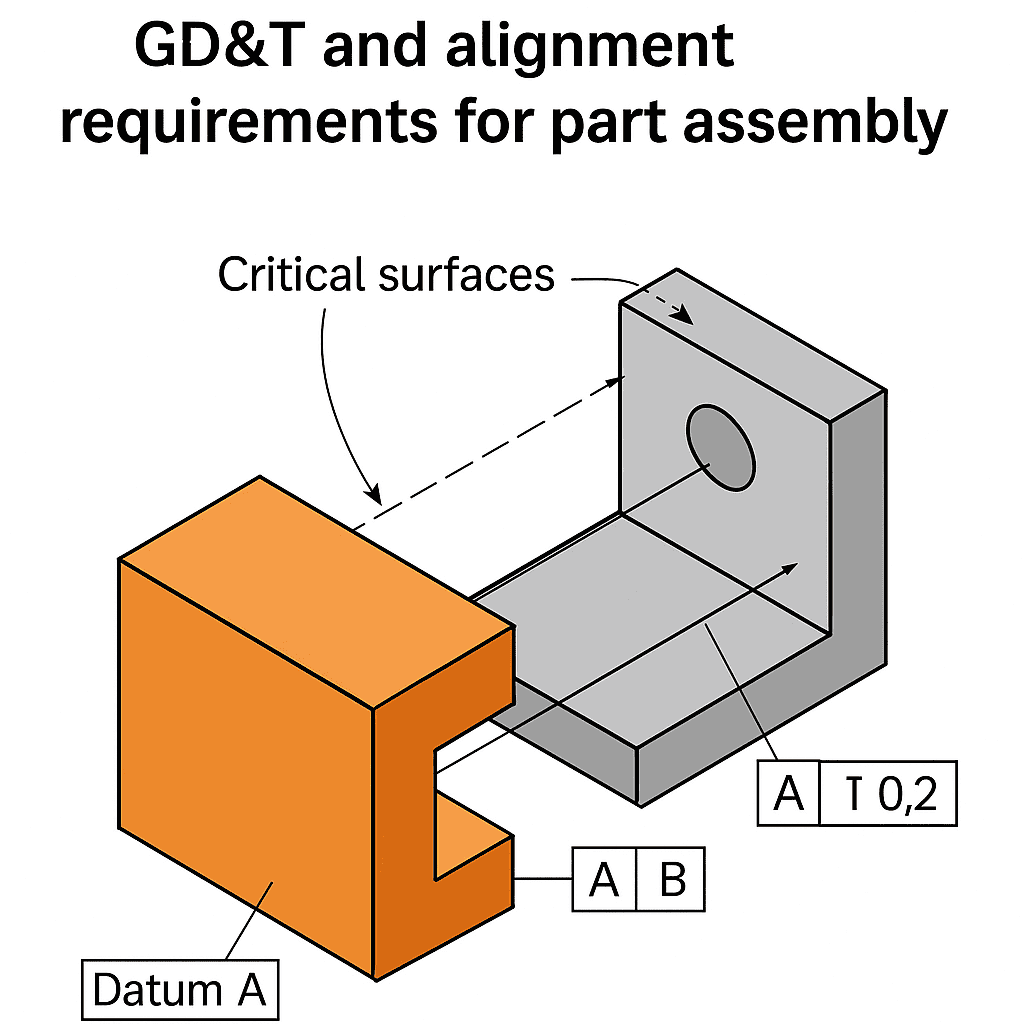

Customers often provide us with 2D drawings and ask for a quote or a sample without offering insight into the part’s role within the larger assembly. Without knowing which surfaces are critical to function, or how the part aligns with its mating counterparts, we cannot identify which dimensions affect assembly or performance—or how they affect them. As a result, we may fail to apply proper control to those dimensions using appropriate GD&T, increasing the risk of misfit or functional failure down the line.

As a result, problems arise:

– The initial sample is machined and delivered.

– Assembly begins—but alignment, fit, or function fails.

– Only then do we receive additional information about the part’s purpose.

– We must then rework the design, redefine key dimensions and tolerances, and produce another round of samples.

This back-and-forth easily adds weeks or even months to the development timeline.

How Early Information Sharing Prevents Delays

When customers share their assembly requirements and design intent early on, we can:

– Identify critical-to-function dimensions and set appropriate tolerances.

– Help define functional datum references for effective inspection and control.

– Reduce the risk of fitment issues such as angular misalignment, interference with adjacent components, cumulative tolerance stack-up, or gaps that affect sealing or visual quality during assembly.

– Optimize manufacturing strategies for cost and repeatability.

In short, the more we understand, the more we can help.

Strict Confidentiality, Guaranteed

We understand that customers may hesitate to share sensitive design information. That’s why we always work under strict NDA (Non-Disclosure Agreements). Our goal is not to reverse-engineer or replicate your designs—but to ensure the part we supply works perfectly in your application.

A Proven Approach to Faster, Smarter Development

This collaboration-first approach is not theoretical—we’ve helped many customers solve assembly issues, reduce iteration cycles, and launch products faster. In several cases, we’ve even helped redefine tolerances to simplify inspection while maintaining function, which also brought cost benefits.

Conclusion

If you’re looking to reduce your development cycle and avoid frustrating delays, consider sharing more than just the drawing. Tell us the part’s purpose, how it fits, and what truly matters. We think like a manufacturer, not just a middleman—and your success is our goal.

Let’s build it right the first time.